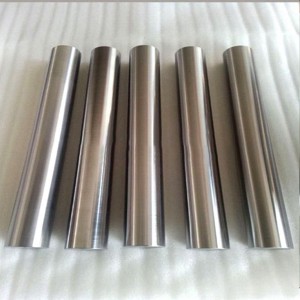

Pris Plât Nb Taflen Niobiwm Purdeb 99.95% wedi'i Addasu'n Uniongyrchol gan y Ffatri Fesul Kg

Paramedrau Cynnyrch

| Enw'r cynnyrch | Taflen Niobiwm Purdeb Uchel 99.95% Cyfanwerthu Plât Niobiwm Pris Niobiwm Fesul Kg |

| Purdeb | Nb ≥99.95% |

| Gradd | R04200, R04210, R04251, R04261, Nb1, Nb2 |

| Safonol | ASTM B393 |

| Maint | Maint wedi'i addasu |

| Pwynt toddi | 2468℃ |

| Pwynt berwi | 4742℃ |

Maint y Plât (0.1 ~ 6.0) * (120 ~ 420) * (50 ~ 3000) mm:

| Trwch | Y trwch gwyriad a ganiateir | Lled | Y gwyriad a ganiateir Lled | Hyd | |

| Lled>120~300 | Lled>300 | ||||

| 0.1~0.2 | ±0.015 | ±0.02 | >300~420 | ±2.0 | >100 |

| >0.2~0.3 | ±0.02 | ±0.03 | >200~420 | ±2.0 | >100 |

| >0.3~0.5 | ±0.03 | ±0.04 | >200~420 | ±2.0 | 50~3000 |

| >0.5~0.8 | ±0.04 | ±0.06 | >200~420 | ±2.0 (±5.0) | 50~3000 |

| >0.8~1.0 | ±0.06 | ±0.08 | >200~420 | ±2.0 (±5.0) | 50~3000 |

| >1.0~1.5 | ±0.08 | ±0.10 | >200~420 | ±3.0 (±5.0) | 50~3000 |

| >1.5~2.0 | ±0.12 | ±0.14 | >200~420 | ±3.0 (±5.0) | 50~3000 |

| >2.0~3.0 | ±0.16 | ±0.18 | >200~420 | ±5.0 | 50~3000 |

| >3.0~4.0 | ±0.18 | ±0.20 | >200~420 | ±5.0 | 50~3000 |

| >4.0~6.0 | ±0.20 | ±0.24 | >200~420 | ±5.0 | 50~3000 |

Gofyniad Mecanyddol (Cyflwr wedi'i anelio):

| Gradd | Cryfder tynnol δbpsi (MPa), ≥ | Cryfder cynnyrch δ0.2, psi (MPa), ≥ | Ymestyniad mewn hyd mesurydd 1"/2", %, ≥ |

| RO4200-1RO4210-2 | 18000 (125) | 12000 (85) | 25 |

| Cyfansoddiad cemegol (%) | ||||||||||||

| Nb | Fe | Si | Ni | W | Mo | Ti | Ta | O | C | H | N | |

| Rhif 1 | Gweddill | 0.004 | 0.002 | 0.002 | 0.004 | 0.004 | 0.002 | 0.07 | 0.015 | 0.005 | 0.0015 | 0.003 |

| Nb2 | Gweddill | 0.02 | 0.02 | 0.005 | 0.02 | 0.02 | 0.005 | 0.15 | 0.03 | 0.01 | 0.0015 | 0.01 |

Mantais

Dwysedd Isel a Chryfder Penodol Uchel

♦ Gwrthiant Cyrydiad Rhagorol

♦ Gwrthiant da i effaith gwres

♦ Di-magnetig a Diwenwyn

♦ Pwynt toddi uchel, gwrth-cyrydiad da, uwch-ddargludiad rhagorol a nodweddion unigryw eraill.

Cais

♦ Diwydiant electronig, Cemeg, Electronig, Diwydiant fferyllol.

♦ Dur, Cerameg, Electroneg, diwydiannau ynni niwclear a thechnoleg uwchddargludyddion.

♦ Ingotau bwrw metel ac asiantau aloi uwch-ddargludol.

♦ Defnyddir yn helaeth wrth gynhyrchu gwahanol fathau o ddur aloi, aloi tymheredd uchel, gwydr optegol, offer torri, deunyddiau uwchddargludol a diwydiannau eraill.